In the ubiquitous world of horizontal ANSI pumps…all share some common dimensions and a back pull-out feature but note there are also two distinctly different styles.

Both styles utilize an external feature to adjust the impeller clearance. This adjustment device helps the owner to set and later re-establish pump performance and efficiency by axially compensating for wear…all without disassembly of the pump.

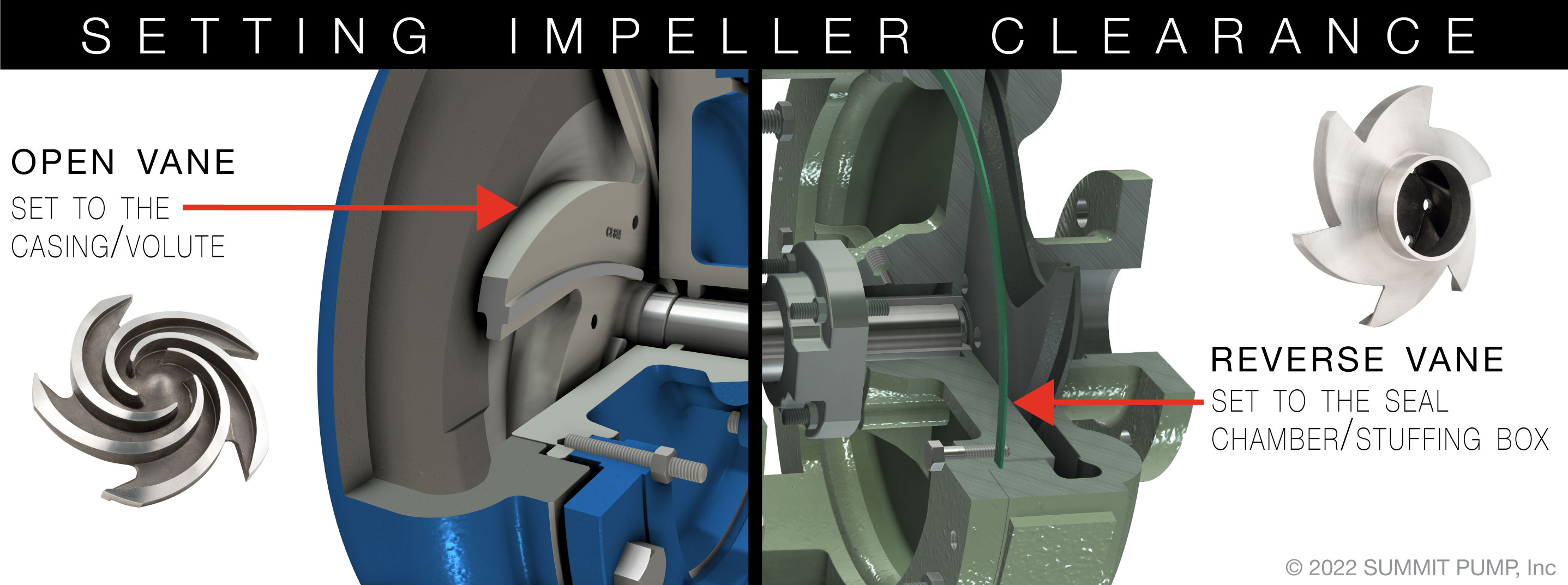

Two ChoicesOn one style; the open/semi-open vane impeller, operating clearance is set to the casing/volute and on the other style, the reverse vane impeller it is the opposite…that is, the clearance is set to the seal chamber/stuffing box. For either style the purpose of the adjustment mechanism is twofold. First to set the initial clearance for the pump size and product temperature and then later when wear inevitably occurs… you can re-adjust the clearance to regain performance and efficiency.  Both impeller designs have their pros and cons. For example, the reverse vane impeller can be accurately set without the casing in the safe and controlled environment of a shop. The open impeller design normally offers a larger wear area that may translate to longer periods of reliable and less costly operation. The reverse vane impeller presents a consistent lower seal chamber pressure (note: check for vapor pressure issues). The open impeller handles stringy and fibrous solids better. Please note that Summit Pump offers both styles. For more details on the advantages and disadvantages of either style please contact your Regional Sales Manager. Regardless of which type of pump you choose; the initial impeller clearance must be set prior to commissioning the pump in the field. The actual clearance specification varies as a function of the pump size and the product temperature. See your Instruction and Operating Manual (IOM) or contact our engineering department for details. Even if the purchase order specified the factory to set the impeller clearance at a certain dimension you should always recheck the clearance in the field to verify the setting is correct. Unless there was an unbroken chain of custody with the pump, you cannot be positive and besides, it is easy to check.

Why Do You Care if the Impeller is Set Incorrectly? As clearance increases pump efficiency decreases. You are effectively reducing the impeller’s size when the clearance increases. Just 0.015 to 0.020 inches off the correct clearance can reduce the performance of a 10-inch impeller to perform like 9.5 inches.  The general “rule of thumb” is that the pump will lose about 1% of its capacity for each 0.001 inches of impeller clearance for the first 0.005 to 0.008 inches of added clearance over the initial setting. The issue gets markedly worse with increasing clearance.

Pump Tips - On average you can adjust the impeller for component wear three times before the pump should come apart for closer inspection and before the clearance has doubled.

- When you adjust the impeller, you are also changing the setting on the mechanical seal. On the open impeller style, you will be reducing seal face pressure and on the reverse vane you will be increasing seal face pressure. Resetting the seal may also be required.

- On the open impeller style, the axial thrust will increase each time the impeller is adjusted due to the impeller’s back pump out vanes moving farther from the seal chamber. The effect will increase the axial thrust and reduce bearing life.

- Net Positive Suction Head Required (NPSHR) increases as clearances open.

- Regardless of the wear location, the seal chamber/stuffing box or the casing/ volute, there is also some wear on the impeller. Post repair or new, we highly recommend that before the pump is commissioned to measure and record total axial travel of the rotating element. With this benchmark information you can measure total travel at later intervals and compare. You will not know exactly which component is wearing or by how much, but you will have an important metric data point to help in the maintenance decision process.

|